BGA chip reballing

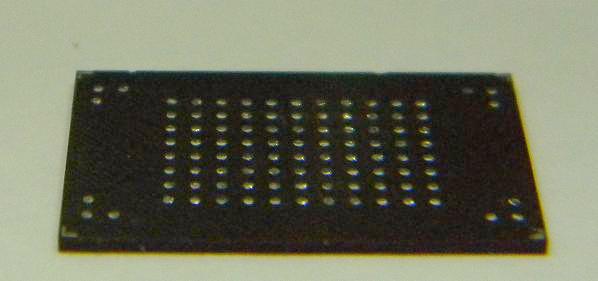

1. Clean up the pads on the chip from residues of solder

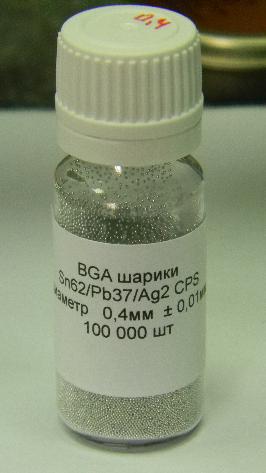

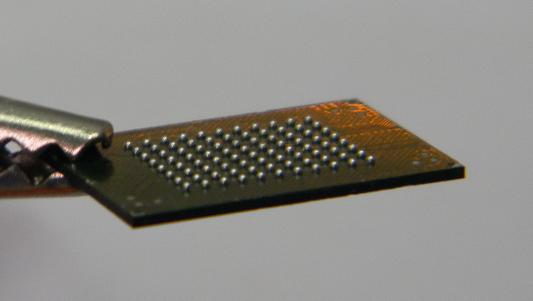

2. Use BGA balls like shown on picture or the same. Diameter must be not less than 0.4mm and not more than 0.45mm

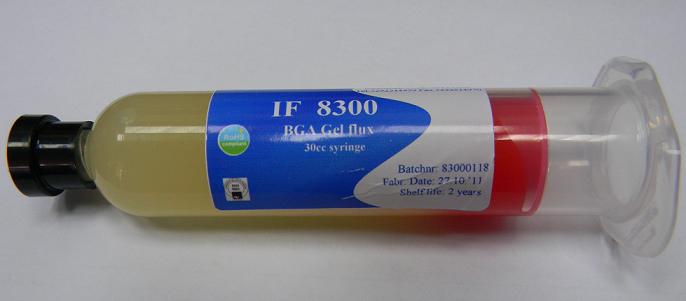

3. Use BGA Gel flux like shown on picture or the same

4. Apply a thin layer of flux over the entire surface of the contact group Remove excess flux.

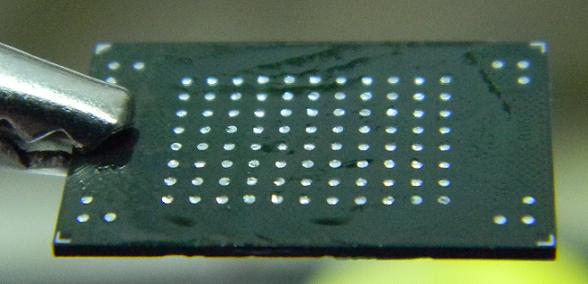

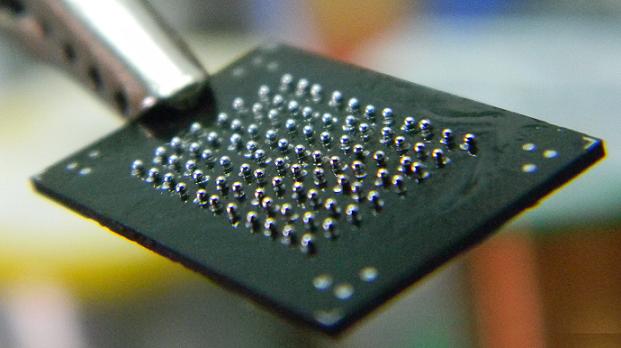

5. Place balls on the pads by a thin pair of tweezers. Make sure the balls not roll from the pads, and not stick together/other

6. Use hot air gun to the bottom of chip. Set temperature 300-310° C. Do not expose the air stream onto the working surface!

7. After the warm-up by heating gun balls will be placed at the contact pads by themselves. Remove excess of flux from chip at the end of job